Mechanical Testing

Mechanical Testing – ISO 527-4

Metals

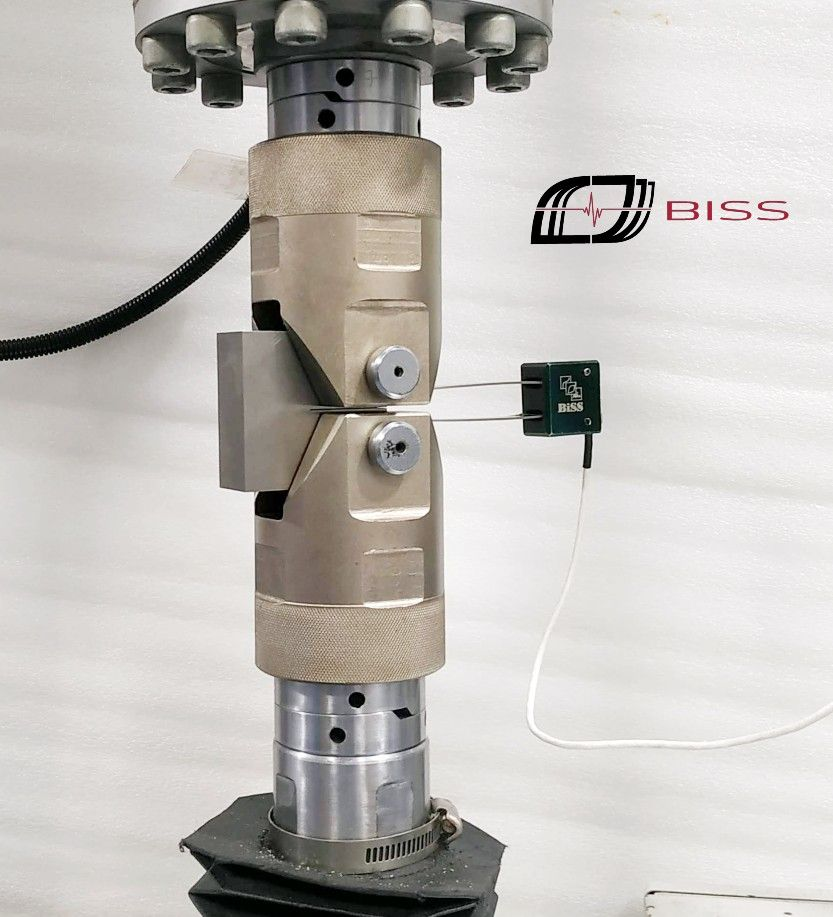

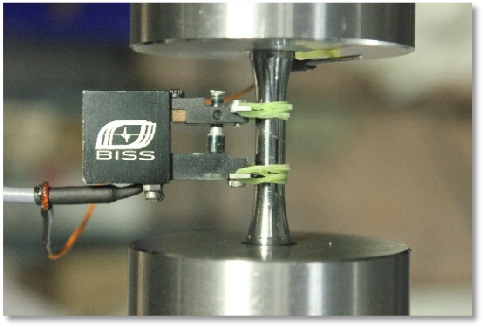

- Tensile Test as per ASTM E8

- Compression test as per ASTM E9

- Tensile Test at Elevated Temperature as per ASTM E 21

- Poisson’s Ratio as per ASTM E132

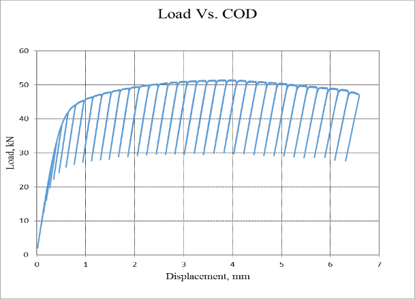

- K1C as per E399

- J1C test as per ASTM E1820

- Constant Force Amplitude Axial Fatigue Test as per ASTM E466

- Low Cycle Fatigue Test as per ASTM E606

- Fatigue Crack growth test as per ASTM E647/IS 16651

- Creep Fatigue Test as per ASTM E2714

- Thermo-Mechanical Fatigue Test as per ASTM E2368

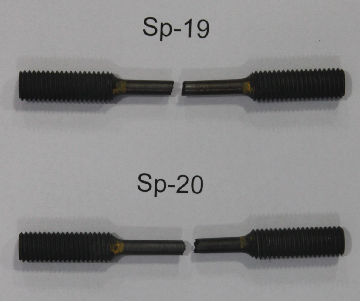

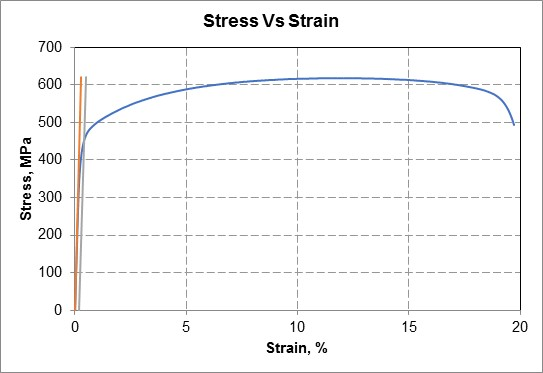

Tensile Test – ASTM E8

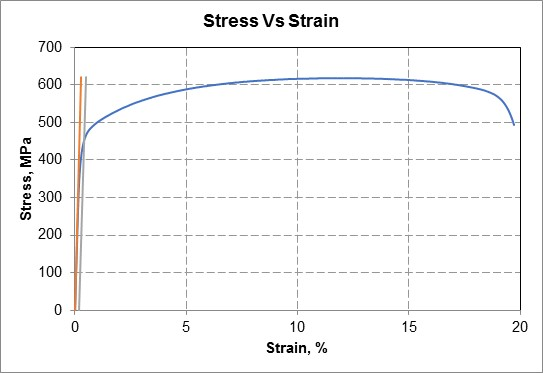

Tension tests provide information on the strength and ductility of materials under uniaxial tensile stresses. This information may be useful in comparisons of materials, alloy development, quality control, and design under certain circumstances.

The results of tension tests of specimens machined to standardized dimensions from selected portions of a part or material may not totally represent the strength and ductility properties of the entire end product or its in-service behavior in different environments.

These test methods are considered satisfactory for acceptance testing of commercial shipments. The test methods have been used extensively in the trade for this purpose.

ASTM E8 method cover the tension testing of metallic materials in any form at room temperature, specifically, the methods of determination of yield strength, yield point elongation, tensile strength, elongation, and reduction of area.

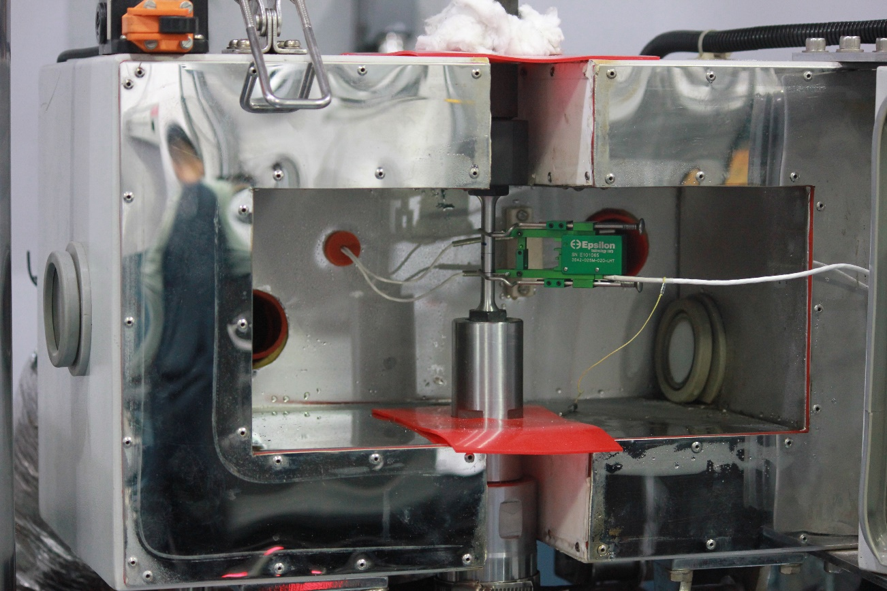

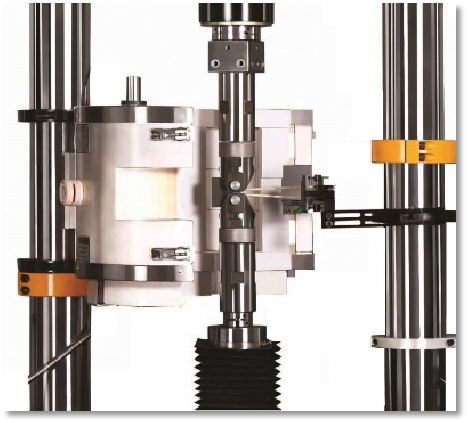

Tensile Test – ASTM E21

The elevated-temperature tension test gives a useful estimate of the ability of metals to withstand the application of applied tensile forces. Using established and conventional relationships it can be used to give some indication of probable behavior under other simple states of stress, such as compression, shear, etc.

ASTM E21 methods cover procedure and equipment for the determination of tensile strength, yield strength, elongation, and reduction of area of metallic materials at elevated temperatures

Metals – Fracture Toughness Test

- Test type – Fracture Toughness Test (FCGR, K1c, J1c)

- Test temperature – (-150°C to 1000 °C)

- Sample Geometry – Compact Tension