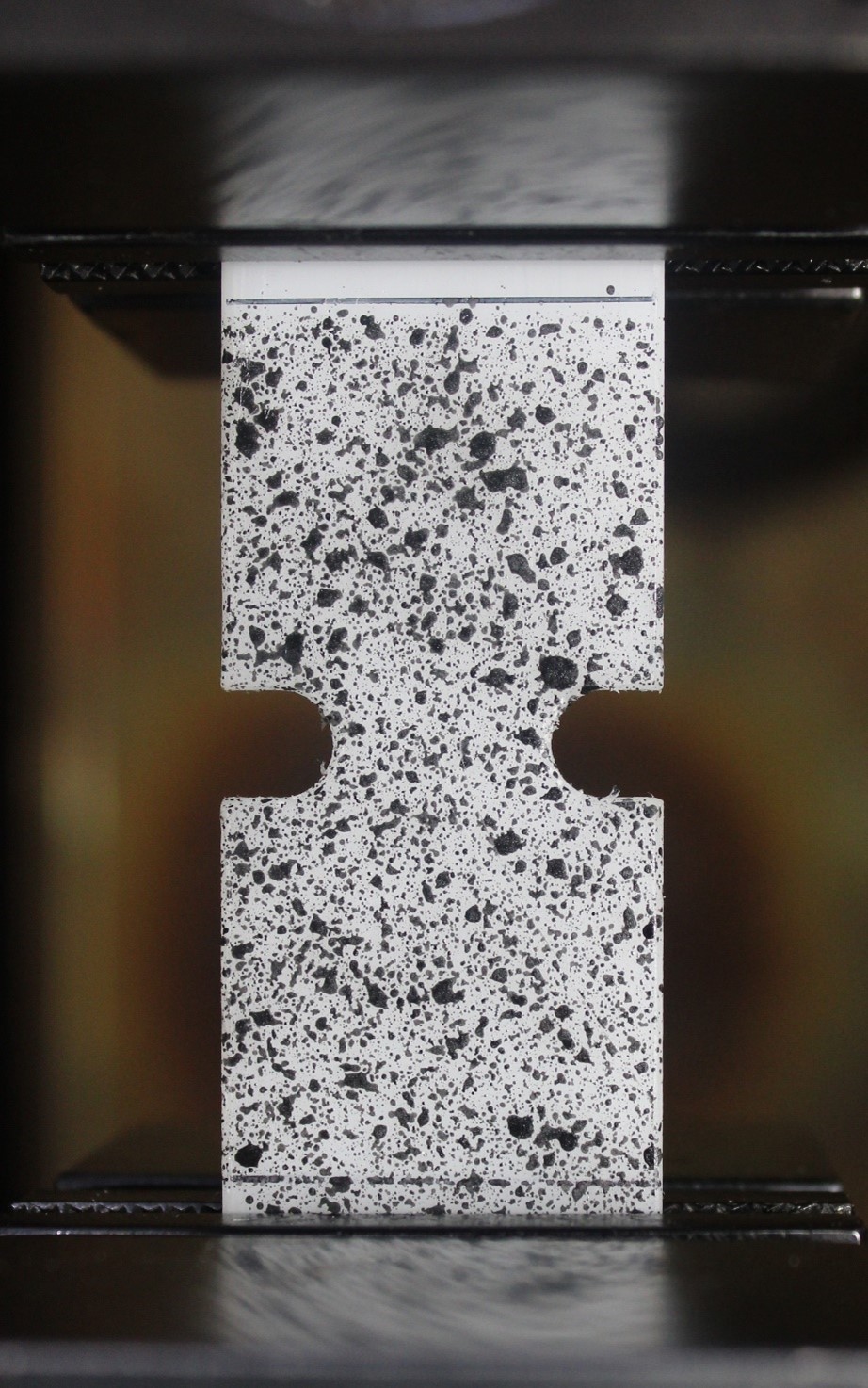

Compression Test ->

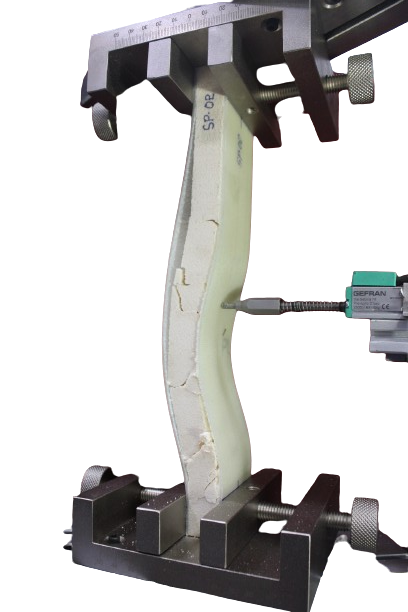

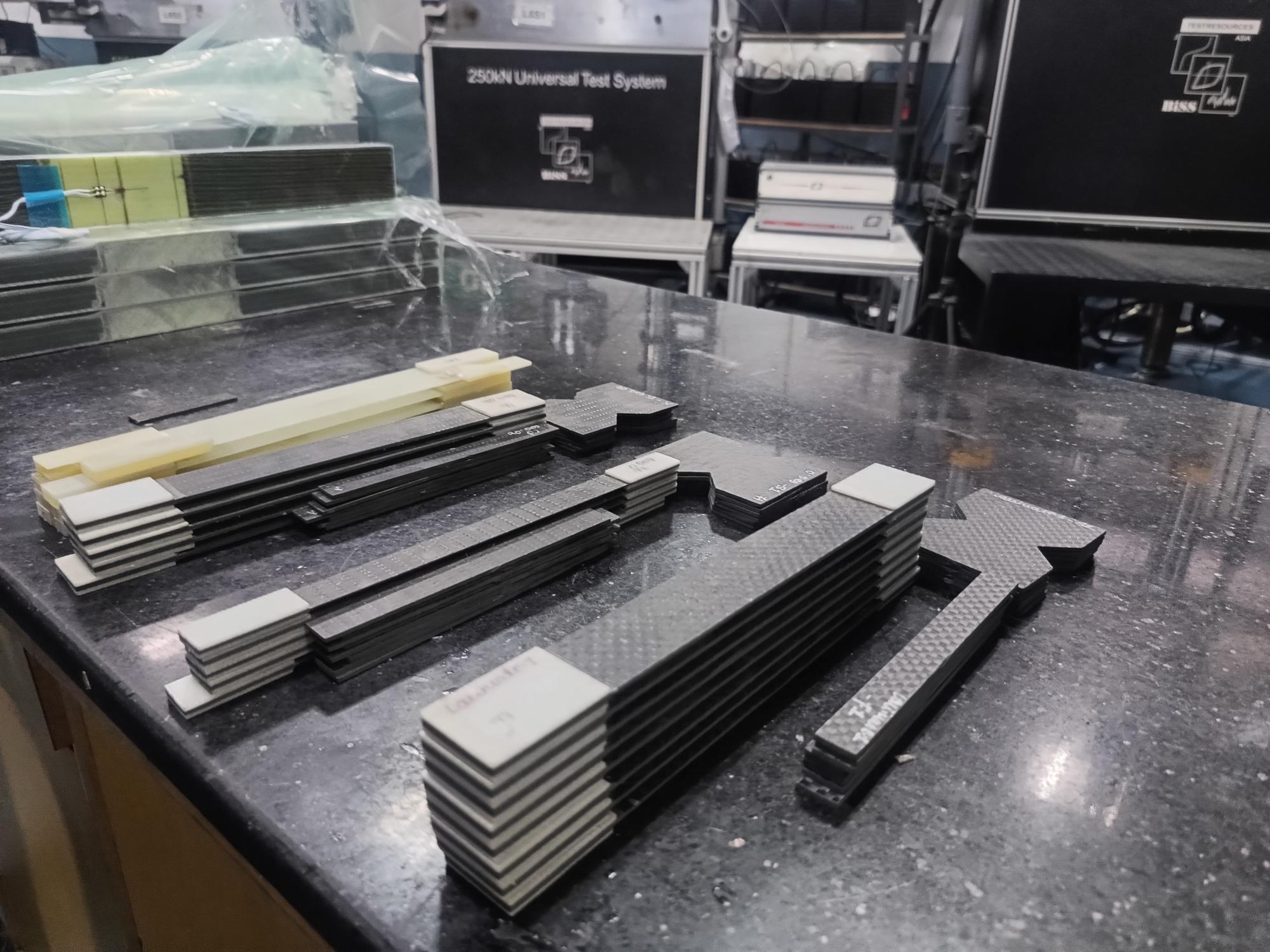

Composite materials are widely used across various industries due to their unique properties, such as high strength-to-weight ratio, corrosion resistance, and design flexibility.

Due to its wide applications mechanical testing plays vital role. BISS Labs composite expertise provide solutions in Tensile, Compression Testing Flexural, Shear, Fatigue, Impact test many more.

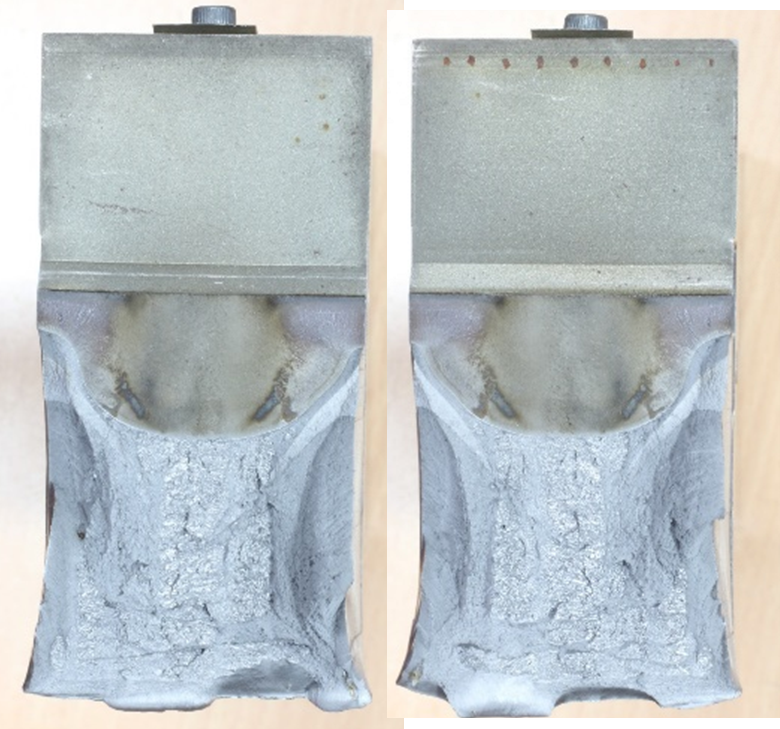

Fracture Mechanics Testing Solutions

Fracture mechanics is a crucial field in engineering and materials science, focusing on the study of crack propagation in materials. Various application includes Structural Integrity Assessment, Failure Analysis, Design and Safety, Material Selection, Life Prediction, Quality Control.

BISS Labs expert testing solution in evaluating K1c, J1c, CTOD, FCGR, CFCGR at elevated and sub-zero temperatures along with various specimen configuration.

Fatigue Testing

Fatigue testing is a vital method used to evaluate how materials behave under repeated stress and cyclic loading. This type of testing helps determine the material’s endurance limit and fatigue life, which are essential for ensuring reliability and safety in various applications.

BISS Labs dynamic test systems and controls will enable fatigue testing of composites, metals, plastics. Stress/Strain controlled fatigue testing with various R-ratio enable S-N curve generation.

Structural Testing

BISS Labs structural testing capabilities allows testing sub-structures and components. Typically testing involves various loading axes and angles on automotive chassis, handlebar, swing arm, lower control arm, steering column, aero-structures, latches and many more.

Our Services

Composite Testing

One stop solution for mechanical testing of Glass and Carbon Reinforced Composites

Fracture Mechanics Testing

Complete package to determine Fatigue Crack Growth and Fracture Toughness under corrosive, elevated and sub-zero environment.

Plastic Testing

Best in class mechanical testing of rigid and highly viscous plastics. Strain rate dependent tests for crash applications.

Structural Testing

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

About Us

India’s First Laboratory to get NADCAP-MTL Accreditation.

BISS Labs operate a state-of-the-art, 24X7 mechanical testing facility with over 30 servo-hydraulic Universal Testing Machines, Structural Actuators and several customized test rigs partnering customers in Aerospace, Defence, Automotive and Energy sectors including Oil & Gas, Wind Energy and Nuclear Power. BISS LABS certified as per ISO/IEC 17025:2017 (NABL), BIS, DGAQA in Mechanical Testing.

Our Industries

WIND ENERGY

We deliver exceptional composite testing solution such Tensile, ILSS, Compression, Fatigue including test specimen manufacturing. BISS Labs is one stop solution for Composite Material Qualification.

INDUSTRIES

Energy

Energy is a subset of renewable energy and represents those renewable energy resources and technologies that provide the highest environmental benefit. The U.S. voluntary market defines green power as electricity produced from solar, wind, geothermal, biogas, eligible biomass, and low-impact small hydroelectric sources. Customers often buy green power for its zero emissions profile and carbon footprint reduction benefits.

AEROSPACE

BISS Labs is accredited for NADCAP-MTL providing solutions to Tensile, Compression, High Cycle Fatigue, Fracture Toughness, Crack Propagation/Crack Growth Tests .

INDUSTRIES

Aerospace

Aerospace is a manufacturing industry involving high-technology that produces aircraft, guided missiles, space vehicles, aircraft engines, propulsion units, and related parts. Some of the industry’s focus is geared toward the government, including defense and security, but also includes commercial and civil airliners, satellite and space systems, and technical operations.

As the aerospace industry advances in technology and innovation to find lighter, stronger, and more advanced materials to fulfill the multitude of aero-related materials and products, Westmoreland Mechanical Testing & Research, Inc. has the expertise for any operational and commercial testing needs. As a world leader in materials testing, we have a proven track record of ensuring prestigious aerospace brands’ competitive advantage through testing solutions and research services.

HEALTHCARE

Industry demands complex and stringent test requirements. BISS Labs expertise in low force applications can provide solutions in testing implants, injector, sutures, bone screws and many more.

INDUSTRIES

medical

The medical technology industry in the United States remains to be the largest medical device market in the world with a market share with hundreds of billions of dollars in revenue, with steady growth potential in exports. The medical technology industry is dominated in regions known for existing technology industries including microelectronics and biotechnology. Investment and capital production remains to be at the forefront of domestic medical technology, with an increase in manufacturers, research & development investment, and technology advances. The medical industry intersects with several technologies related sectors including microelectronics, telecommunications, instrumentation, biotechnology, and software development.

Collaboration has led to recent advances including neuro-stimulators, stent technologies, biomarkers, robotic assistance, and implantable electronic devices. The industry is fueled by innovation and medical diagnoses; Westmoreland Mechanical Testing & Research, Inc. provides crucial testing for the medical industry, providing reliable, innovative, and adaptive testing and research for the latest technologies, devices, and apparatuses. We provide extensive and critical results for testing materials and components for medical applications. Providing these results allows our customers to have assurance for such significant testing, ensuring reliable and accurate materials for end-consumer goods and products.

Research And Development

Extensive research on very high temperature up to 1600 C and fatigue crack growth methodologies.

INDUSTRIES

Aerospace

Aerospace is a manufacturing industry involving high-technology that produces aircraft, guided missiles, space vehicles, aircraft engines, propulsion units, and related parts. Some of the industry’s focus is geared toward the government, including defense and security, but also includes commercial and civil airliners, satellite and space systems, and technical operations.

As the aerospace industry advances in technology and innovation to find lighter, stronger, and more advanced materials to fulfill the multitude of aero-related materials and products, Westmoreland Mechanical Testing & Research, Inc. has the expertise for any operational and commercial testing needs. As a world leader in materials testing, we have a proven track record of ensuring prestigious aerospace brands’ competitive advantage through testing solutions and research services.

AUTOMOTIVE

Industry demands complex and stringent test requirements. BISS Labs expertise in low force applications can provide solutions in testing implants, injector, sutures, bone screws and many more.

INDUSTRIES

Aerospace

Aerospace is a manufacturing industry involving high-technology that produces aircraft, guided missiles, space vehicles, aircraft engines, propulsion units, and related parts. Some of the industry’s focus is geared toward the government, including defense and security, but also includes commercial and civil airliners, satellite and space systems, and technical operations.

As the aerospace industry advances in technology and innovation to find lighter, stronger, and more advanced materials to fulfill the multitude of aero-related materials and products, Westmoreland Mechanical Testing & Research, Inc. has the expertise for any operational and commercial testing needs. As a world leader in materials testing, we have a proven track record of ensuring prestigious aerospace brands’ competitive advantage through testing solutions and research services.

HEALTHCARE

.